Chitsulo Choyaka Chothira Dip

Makulidwe a khoma (mm): 2.0, 2.5, 2.8, 3.2, 3.5, 3.8, 4.0, 4.5.

Magawo apakati (c): 1.064, 1.051, 1.045, 1.040, 1.036, 1.034, 1.032, 1.028.

Zindikirani: Zomwe zimapangidwira zitsulo ndizofunika kwambiri kuti zitsimikizire kuti ntchito yomaliza (makina) yazitsulo, ndipo zimadalira mankhwala a zitsulo ndi njira yopangira kutentha. Muyeso wa chitoliro chachitsulo, malinga ndi zofunikira zosiyanasiyana zogwiritsira ntchito, mawonekedwe osunthika (mphamvu yamakokedwe, mphamvu zokolola kapena zokolola, elongation),kuuma ndi kulimba indexers amatchulidwa, komanso kutentha kwapamwamba ndi kutsika komwe kumafunidwa ndi ogwiritsa ntchito.

Makalasi achitsulo: Q215A; Q215B; Q235A; Q235B.

Mayeso kuthamanga mtengo/Mpa: D10.2-168.3mm ndi 3Mpa; D177.8-323.9mm ndi 5Mpa

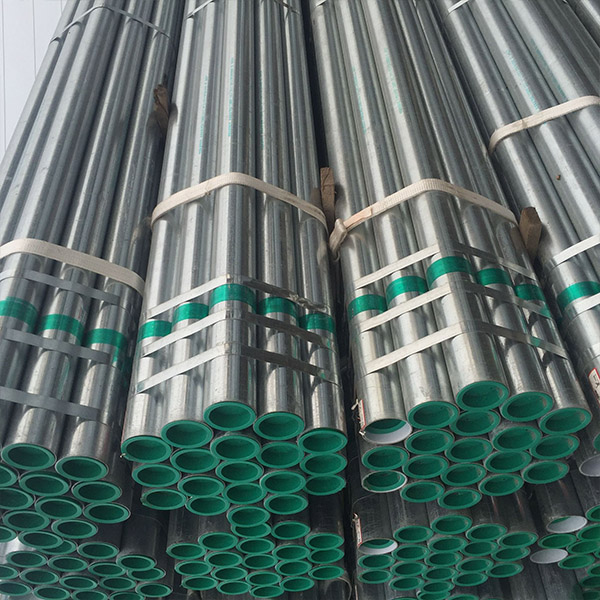

Miyezo ya dziko ndi kukula kwa mipope ya malata

GB/T3091-2015 Welded zitsulo chitoliro kwa otsika kuthamanga madzimadzi mayendedwe

GB/T13793-2016 Longitudinal magetsi welded zitsulo chitoliro

GB/T21835-2008 welded zitsulo chitoliro kukula ndi unit kutalika kulemera

Njira yotuluka ndi:wakuda chubu-za alkaline kutsuka-madzi ochapira-wotolera-madzi ochapira-kuwotchera aid-kuyanika-kutentha kuviika galvanizing-kunja kuwomba-mkati kuwomba-mpweya kuziziritsa-madzi kuziziritsa -Pasivation-madzi rinsing-kuyang'ana-kuyesa-kusungirako.

Mapaipi omwe amanenedwa kawirikawiri, malata amagwiritsidwa ntchito popanga gasi, komanso mtundu wa mapaipi achitsulo omwe amagwiritsidwa ntchito potenthetsera nawonso ndi mapaipi a malata. Mipope ya galvanized imagwiritsidwa ntchito ngati mapaipi amadzi. Pambuyo pazaka zingapo zogwiritsira ntchito, dzimbiri ndi dothi zambiri zimapangidwira m'mipope, ndipo madzi achikasu omwe amatuluka sikuti amangoipitsa zinthu zaukhondo , Ndipo zimasakanizidwa ndi mabakiteriya omwe amabala pakhoma lamkati lamkati, ndipo kuwononga kumayambitsa. kuchuluka kwa zitsulo zolemera m'madzi, zomwe zimawononga kwambiri thanzi la munthu.

Njira yolumikizira chitoliro chachitsulo chagalvanized: ulusi, welded.

Mgwirizano wa groove

(1) Kusweka kwa ma roll groove weld

1. Yalani nthiti zowotcherera za khoma lamkati la nthiti zowotcherera mbali ya nozzle kuti muchepetse kukana kwa poyambira.

2, Sinthani nsonga ya chitoliro chachitsulo ndi zida zogubuduza, ndipo funani chitoliro chachitsulo ndi zida zopukutira kuti zikhale zosalala.

3. Sinthani liwiro la poyambira, ndipo poyambira kupanga nthawi sangadutse zomwe zikunenedwa, gwiritsani ntchito mphamvu molingana komanso pang'onopang'ono.

(2) Pereka poyambira zitsulo chitoliro kusweka

1. Yalani nthiti zowotcherera zamkati zamkati mwa nthiti zapakamwa kuti muchepetse kukana kwa poyambira.

2, Sinthani nsonga ya chitoliro chachitsulo ndi zida zogubuduza, zomwe zimafuna kuti chitoliro chachitsulo ndi zida zogubuduza zikhale zofanana.

3. Sinthani liwiro lokakamiza, kuthamanga kwapang'onopang'ono sikungadutse zomwe zikunenedwazo, gwiritsani ntchito mphamvu molingana ndi pang'onopang'ono.

4. Yang'anani m'lifupi ndi chitsanzo cha chodzigudubuza chothandizira ndi choponderetsa cha zida zopukutira, ndipo muwone ngati pali kusagwirizana mu kukula kwa odzigudubuza awiri, zomwe zingayambitse kulanda.

5. Gwiritsani ntchito vernier caliper kuti muwone ngati groove ya chitoliro chachitsulo imatchulidwa.

(3) Poyambira wopangidwa ndi makina opukutira akuyenera kukwaniritsa izi

1, Pamwamba pa mapeto a chitoliro ku chigawo cha groove chiyenera kukhala chosalala komanso chopanda kusagwirizana ndi zizindikiro.

2, Pakatikati pa groove iyenera kukhala yokhazikika ndi khoma la chitoliro, m'lifupi ndi kuya kwa poyambira kuyenera kukwaniritsa zofunikira, ndikuwona ngati gawo laling'ono ndilolondola.

3. Ikani mafuta pa mphete yosindikizira ya rabara ndikuwona ngati mphete yosindikizira ya rabala yawonongeka. Chidacho sichiyenera kukhala chopangira mafuta.

Kulumikizana kwa welded

1. Pakamwa pa chitoliro cha chitoliro chachitsulo chosakanizidwa sichikuyenda molunjika ndipo pali vuto ndi pakamwa pa oblique wa chitoliro chachitsulo pambuyo powombera. Ndi bwino kudula mutu wa chitoliro kwa nthawi yochepa musanayambe kukonza.

2, pambuyo kanasonkhezereka zitsulo chitoliro nozzles olumikizidwa, nozzles awiri si zolimba ogwirizana, chifukwa m'lifupi makulidwe a welded olowa; ndipo chitolirocho ndi elliptical chifukwa cha zifukwa zake kapena mabampu oyendetsa. Ndibwino kuti mudule mutu wa chitoliro kwa nthawi yochepa. Njira kachiwiri.

3. Mipopu ya mipope yachitsulo ikathiridwa, matuza amawonekera pamphuno:

4. Chifukwa cha luso zifukwa pa kuwotcherera.

5. Mu mphuno muli zinki tinatake tozungulira, zomwe zingayambitse kuwotcherera zovuta ndi matuza. Ngati tinthu tating'onoting'ono ta zinki ndi zazikulu kwambiri komanso mapaipi ochulukirapo, tinthu tating'ono ta zinki tichotsedwe.

Kulumikizana kwa waya

1, Buckle Wopangidwa ndi ulusi: Chitoliro cha chitoliro ndi chingwe cha ulusi sizingalumikizidwe kwathunthu, kumasula, kudula gawo lachingwe, ndikuyikanso ulusiwo.

2. Ulusi wachitsulo wachitsulo ndi ulusi wa hoop wa chitoliro sizikugwirizana ndipo sizingagwirizane. Chitoliro cha chitoliro chiyenera kusinthidwa kapena zipangizo zisinthidwe ndikuziikanso ulusi.

3. Kusowa kusindikizidwa pambuyo poti chitoliro chachitsulo chatsekedwa: Yesani ngati makulidwe a khoma la chitoliro chachitsulo angakwaniritse zofunikira za makulidwe a chitoliro cha ulusi