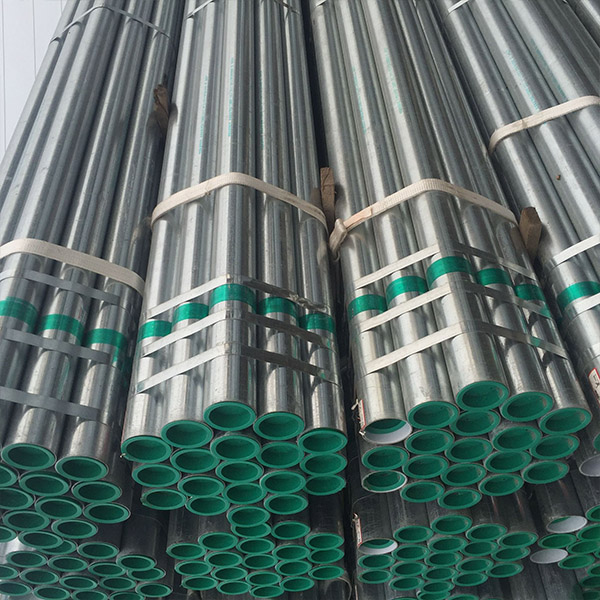

Chitoliro cha Galvanized

Njira yotuluka ndi:wakuda chubu-za alkaline kutsuka-madzi ochapira-wotolera-madzi ochapira-kuwotchera aid-kuyanika-kutentha kuviika galvanizing-kunja kuwomba-mkati kuwomba-mpweya kuziziritsa-madzi kuziziritsa -Pasivation-madzi rinsing-kuyang'ana-kuyesa-kusungirako.

1, Brand ndi mankhwala

Magulu ndi mankhwala a zitsulo zamapaipi azitsulo zopangira malata ayenera kutsatizana ndi kalasi ndi mankhwala azitsulo zazitsulo zakuda monga momwe zafotokozedwera mu GB/T3091.

2, Njira yopanga

Njira yopangira chitoliro chakuda (kuwotchera ng'anjo kapena kuwotcherera magetsi) imasankhidwa ndi wopanga. Kutentha kwa dip galvanizing kumagwiritsidwa ntchito ngati galvanizing.

3. Ulusi ndi chitoliro cholumikizira

(a) Pazipaipi zachitsulo zoperekedwa ndi ulusi, ulusi uyenera kupangidwa pambuyo pokoleza. Ulusi uyenera kutsata malamulo a YB 822.

(b) Mapaipi achitsulo ayenera kutsatira YB 238; mfundo zolumikizira mapaipi achitsulo zosungunuka ziyenera kutsatira YB 230.

4. Makina opangira makina azitsulo zamapaipi achitsulo asanapangire malata ayenera kukwaniritsa zofunikira za GB 3091.

5. Kufanana kwa gulu la malata Chitoliro chachitsulo chopangidwa ndi chitsulo chiyenera kuyesedwa kuti chikhale chofanana ndi chosanjikiza chamalata. Chitsanzo cha chitoliro chachitsulo sichidzasanduka chofiira (chokutidwa ndi mkuwa) chitatha kumizidwa mumkuwa wa sulphate kwa nthawi 5 zotsatizana.

6, Cold kupinda mayeso kanasonkhezereka zitsulo chitoliro ndi awiri mwadzina osapitirira 50mm ayenera ozizira kupinda mayeso. Kopindika ndi 90 °, ndipo utali wopindika ndi 8 kuwirikiza kwakunja. Palibe filler panthawi yoyesera, ndipo weld ya chitsanzo iyenera kuikidwa kunja kapena kumtunda kwa njira yopindika. Pambuyo pa mayeso, pasakhale ming'alu ndi kupukuta kwa nthaka wosanjikiza pa chitsanzo.

7, Mayeso a kuthamanga kwa madzi Mayeso a kuthamanga kwa madzi ayenera kuchitidwa mu clarinet, ndipo kuyesa kwa eddy panopa kungagwiritsidwenso ntchito m'malo mwa kuyesa kuthamanga kwa madzi. Kuthamanga kwa mayeso kapena kukula kwa chitsanzo chofananitsa cha kuyesa kwa eddy panopa kudzakwaniritsa zofunikira za GB 3092. Zochita zamakina zachitsulo ndi zizindikiro zofunika kuti zitsimikizire kuti ntchito yomaliza yogwiritsira ntchito (makina) yachitsulo.

①Kulimba mtima (σb):Mphamvu yochuluka (Fb) yomwe chitsanzocho chimanyamula pamene chikusweka panthawi yotambasula, yogawidwa ndi kupsinjika (σ) komwe kumapezeka pogawaniza gawo loyambirira (So) lachitsanzo, limatchedwa resistance Tensile mphamvu (σb) , unit ndi N/mm2 (MPa). Zimayimira kuthekera kwakukulu kwazinthu zachitsulo kuti zisawonongeke pansi pa mphamvu yamphamvu. Mu chilinganizo: Fb - mphamvu yayikulu yomwe chitsanzocho chimanyamula chikasweka, N (Newton); Kotero-gawo loyambirira lachitsanzo, mm2.

②Zokolola (σs):Kwa zitsulo zachitsulo zomwe zimakhala ndi zochitika zokolola, kupanikizika komwe chitsanzocho chingapitirire kutalika popanda kuwonjezera mphamvu panthawi yotambasula kumatchedwa kuti zokolola. Ngati mphamvu ikutsika, zokolola zapamwamba ndi zotsika ziyenera kusiyanitsa. Gawo la zokolola ndi N/mm2 (MPa). Zokolola Zapamwamba (σsu): Kupanikizika kwakukulu kwa chitsanzocho chisanaperekedwe ndipo mphamvu ikutsika kwa nthawi yoyamba; Zokolola Zotsika (σsl): Kupanikizika kochepa mu gawo la zokolola pamene zotsatira zoyamba zosakhalitsa sizikuganiziridwa. Kumene: Fs--zokolola mphamvu (nthawi zonse) panthawi yokhazikika ya chitsanzo, N (Newton) Kotero - gawo loyambirira lachitsanzo, mm2.

③ Elongation pambuyo kusweka:(σ) Pakuyesa kwamphamvu, kuchuluka kwa kutalika kwa kutalika kwa gauge kumawonjezeka pambuyo poti wathyoledwa mpaka kutalika koyambirira kumatchedwa elongation. Yofotokozedwa ndi σ, unit ndi %. Mu chilinganizo: L1 - kutalika kwa gauge ya chitsanzo pambuyo kusweka, mu mm; L0 - kutalika kwa gauji yachitsanzo, mu mm.

④ Kuchepetsa malo:(ψ) Pakuyesa kwazitsulo, chiwerengero cha kuchepetsa kwakukulu kwa malo ozungulira pamtunda wochepetsetsa wa chitsanzo pambuyo pa kusweka kwachitsanzo kumalo oyambirira kumatchedwa kuchepetsa dera. Zofotokozedwa mu ψ, unit ndi %. Mu chilinganizo: S0 - gawo loyambirira lachitsanzo, mm2; S1 - malo ocheperako pang'onopang'ono pamtunda wocheperako wachitsanzo chikasweka, mm2.

⑤ Kuuma index:Kukhoza kwa zida zachitsulo kukana kulowetsa zinthu zolimba pamtunda kumatchedwa kuuma. Malinga ndi njira zosiyanasiyana zoyesera ndi kuchuluka kwa ntchito, kuuma kumatha kugawidwa mu kuuma kwa Brinell, kulimba kwa Rockwell, kulimba kwa Vickers, kulimba kwa m'mphepete mwa nyanja, kuuma kwakung'ono komanso kuuma kwa kutentha kwambiri. Pali mapaipi atatu omwe amagwiritsidwa ntchito kwambiri: Brinell, Rockwell, ndi Vickers hardness.

Kuuma kwa Brinell (HB):Gwiritsani ntchito mpira wachitsulo kapena mpira wa simenti wa carbide wokhala ndi mainchesi ena kuti muwunikize pamwamba pa sampuli ndi mphamvu yoyesera yodziwika (F), chotsani mphamvu yoyesera itatha nthawi yoikika, ndikuyesa kukula kwa indentation pamwamba pake. chitsanzo (L). Mtengo wa Brinell hardness ndi quotient yomwe imapezeka pogawa mphamvu yoyesera ndi malo ozungulira a indentation. Kuwonetsedwa mu HBS (mpira wachitsulo), unit ndi N/mm2 (MPa).